Search

Thames Water appointed Tamesis – a Joint Venture of Imtech Process and Laing O’Rourke, to deliver and coordinate the development of renewable energy schemes at Beckton Sewage Treatment Works (STW) to include anaerobic digestion aimed at increasing the capacity to treat sewage during heavy rainfall and the growth in population capacity by 400,000 to almost 4 million people.

Thames Water appointed Tamesis – a Joint Venture of Imtech Process and Laing O’Rourke, to deliver and coordinate the development of renewable energy schemes at Beckton Sewage Treatment Works (STW) to include anaerobic digestion aimed at increasing the capacity to treat sewage during heavy rainfall and the growth in population capacity by 400,000 to almost 4 million people.

Based in east London, Beckton STW currently serves a population of approximately 3.5million people and is recognised as one of the largest STWs in Europe.

Following the appointment of the 6MWe combined heat and power (CHP) installation at neighbouring Crossness Sewage Treatment Works, Edina were awarded the contract to supply and install an additional CHP plant at Beckton STW.

As part of an on-going development programme, Thames Water appointed Tamesis (a Joint Venture of Imtech Process and Laing O’Rourke), to co-ordinate the project at Crossness Sewage Treatment Works.

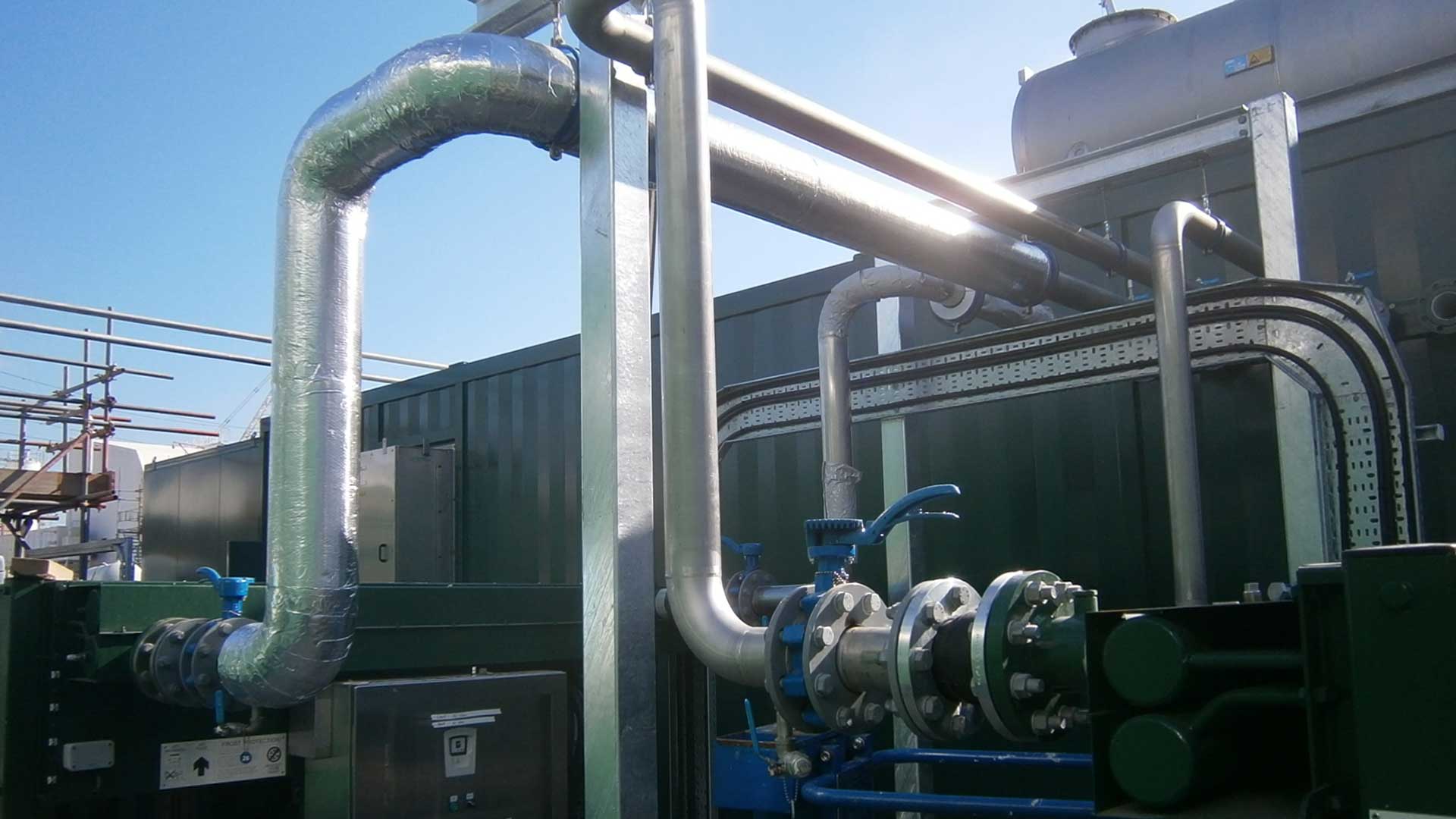

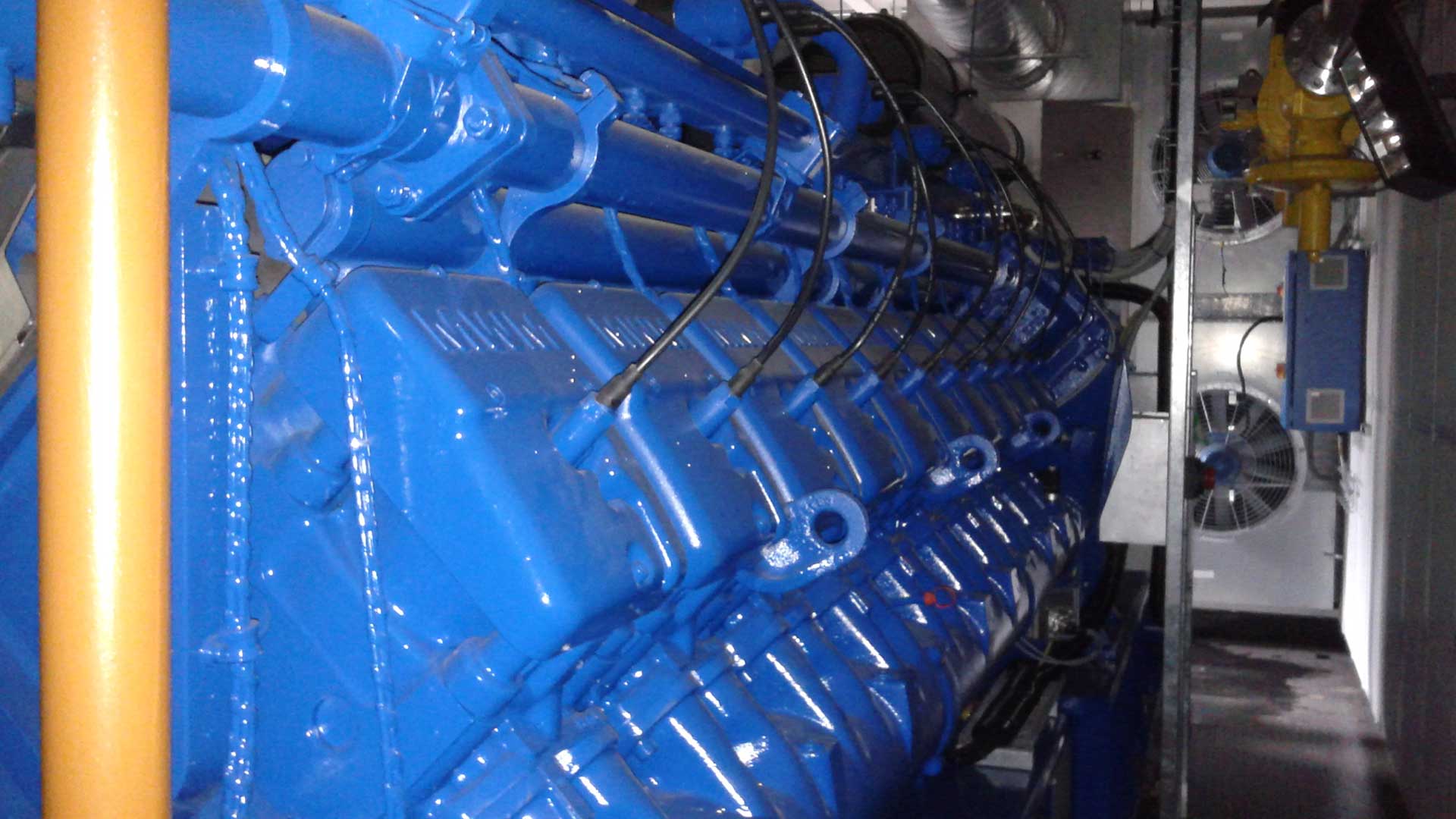

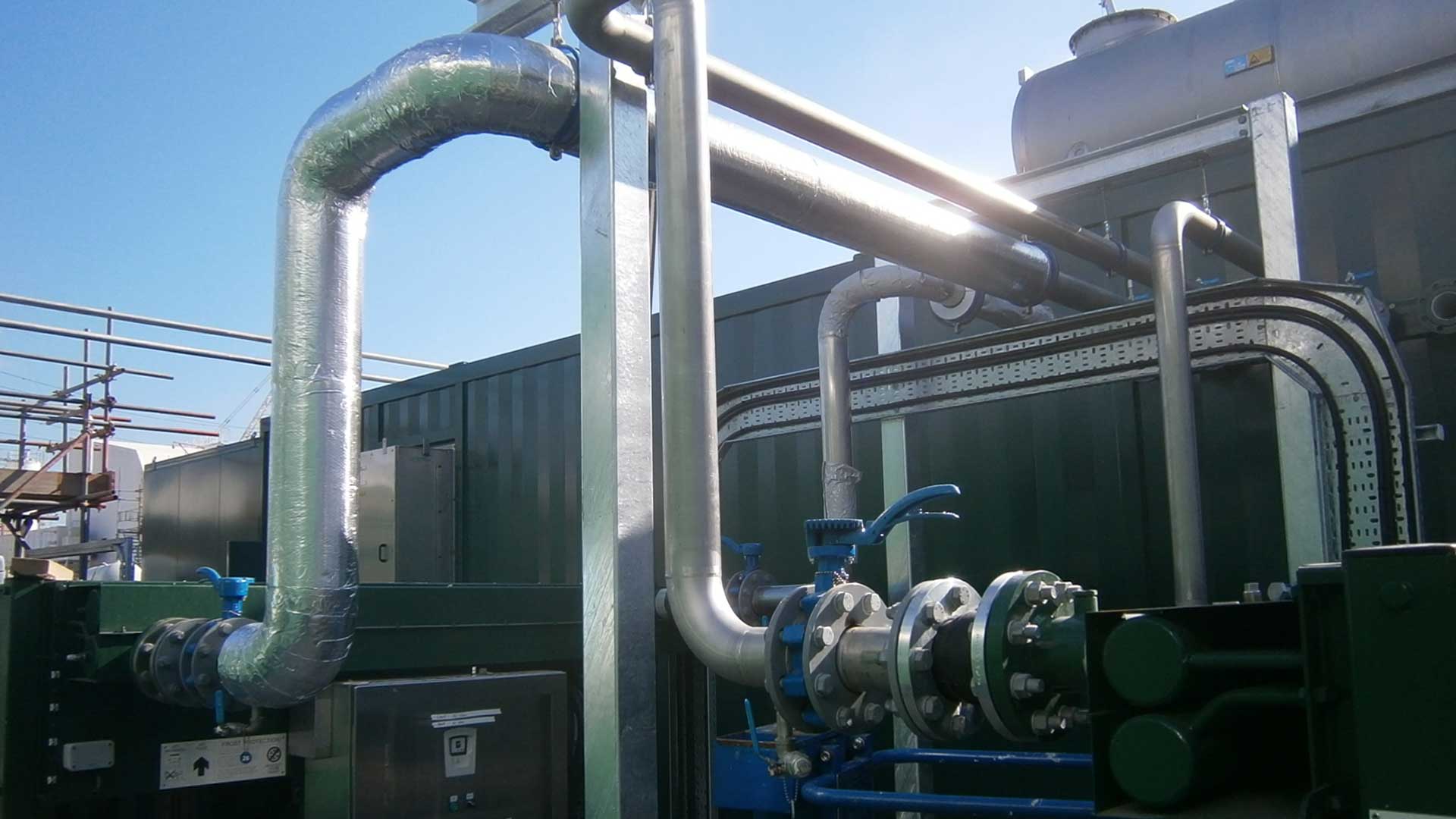

The scope of works included the supply and installation of 6MWe CHP plant, comprising of 3 x 2MWe MWM manufactured TCG 2020 V20 gas engine – offering market leading high electrical efficiency and performance, low operating costs and serviceability.

The contract included a fully inclusive service and maintenance agreement, which provided the client with the lowest lifecycle operating cost.

The thermal hydrolysis plant will burn the highly combustible sewage sludge created after waste water treatment to 160 degrees Celsius, to produce 50 per cent more biogas prior to the anaerobic digestion (AD) process. The biogas will be combusted within the CHP plant to generate electricity and heat used on site with excess sold to the electricity grid.

When combined with the adjacent Crossness STW installation, the 12MWe CHP plants will produce enough electricity to power 24,000 homes. The engine jacket water heat will be used for digester heating with the exhaust fed to waste heat boilers for steam production to assist the advanced digestion process. These gensets habitually operate at an overall efficiency in excess of 85 per cent with uptime of >92 per cent.

The MWM gas engines were containerised in-house at Edina’s manufacturing facility in Lisburn, North Ireland and included all ancillary equipment, expediting installation, commissioning and reducing project costs.

Client:

Tamesis Joint Venture

Location:

London, UK

Capacity:

6MWe

Operational:

2014

Manufacturer:

MWM

Packager:

Edina

Engine Type:

3 x 2MWe TCG 2020 V20

Primary Fuel:

Biogas

Edina CHP reduces operational costs by £100k per week at second largest sewage treatment works in the UK.

Read moreEdina 6MWe CHP increases power production at Crossness Sewage Treatment Works.

Read moreEdina 3.2MWe CHP powers Yorkshire Water’s Esholt Sewage facility saving £1.3million in energy costs.

Read more

Copyright © Edina. All Rights Reserved.