Data centres powered by gas engines can provide operators with a reduced carbon footprint, increased profitability due to the flexibility of the gas engine asset and improve security of supply by addressing grid capacity limitations.

Edina’s data centre generators solution are designed to meet the needs of your data centre requirements and provide operators with a low carbon, secure source of baseload or standby power.

The flexibility of our gas engines enables operators to recover and utilise heat and cooling onsite via Combined Heat and Power (CHP) and Trigeneration application. Operators can generate additional revenue streams in the sale of nonessential heat, and cooling, to community district heating networks and export surplus electrical capacity to the grid to support stability and balance intermittent renewable supply akin to flexible generation plants.

Increased power cost savings

Displacement of higher emissions fuels such as diesel oil

Potential payback within 2-5 years

Greater operational resilience and security of power supply

High electrical and thermal efficiency of up to 90%

Fuel flexibility - renewable, low carbon, and hydrogen ready

Recognised technology within the net-zero pathway

Globally, billions of customers rely on data centres for email, cloud storage and countless other digital services. Data centre infrastructure is instrumental in supporting the economy, helping thousands of businesses connect with employees, partners, and customers.

Powering all this activity takes huge amounts of energy. Global data centre electricity consumption in 2020 was an estimated 240-340 TWh – about 1-1.3% of global electricity consumption. This excludes energy used for cryptocurrency mining, which was estimated to be around 110 TWh in 2022, accounting for 0.4% of annual global electricity demand.

Some forecasters predict that by 2030, demand for data will be 20 times what it was in 2018. With internet traffic and the digitisation of services rising exponentially, data centres will need to ensure they maintain an uninterrupted supply of power as a priority whilst achieving significant energy efficiency gains to keep rising power costs under control.

Energy is typically the largest single overhead for data centres, accounting for up to 60% of operating costs, according to analysis by TechUK. Data centre managers can thus generate uninterruptible power more affordably and efficiently.

The cost saving benefit of Trigeneration is not only due to the fact that it recycles waste heat that can be used as free cooling, but also explained by the economics of using pipeline gas to fuel the technology.

The spark spread, the differential between the cost of grid-supplied electricity and the wholesale gas price, still favours the provision of on-site generation despite recent power price hikes. In this way, high-efficiency gas engines use mains gas to produce electricity and offset their grid electricity cost to deliver a fast return on investment.

That is why proven Trigeneration technology is so widely used by mission critical businesses across the globe. Many organisations use these low carbon power and cooling systems as part of their roadmap to net-zero by re-investing the cost savings in newer sustainable technologies with a longer payback period.

Natural gas fuelled CHP systems play a key role in the transition to a renewable power system. Due to the Merit Order, which determines the order in which power is dispatched (at least cost) from generators to the grid, the generator usually only displaces electricity generated by higher carbon power stations. It is unlikely to displace lower cost renewable and nuclear power.

By generating power on-site and using gas engines, data centres can dramatically reduce demand on the local electricity grid. This is important where there are constraints on the local network, thus enabling facilities to expand quickly, rather than waiting for extra network capacity. On-site gas engines can also facilitate the development of new projects at sites where there is tight grid supply and lengthy delays for new connections.

Flexible Demand, which is a pre-requisite for new grid connections for Data Centres in Ireland, enhances security of supply, allows more renewable power onto the grid and assists in grid management.

In Ireland, which is a major global data centre location for some of the world’s biggest tech firms – grid operator EirGrid projects that electricity demand from data centres and other large energy users will double by 2028. The Irish Academy of Engineering estimates that data centre expansion will require almost €9bn of investment in new energy infrastructure.

World-renowned gas engine manufacturer MWM continues to innovate, ensuring the future of Combined Heat and Power (CHP) and its critical role within the global transition towards net-zero and beyond.

As such, MWM gas engines are capable of 25% blended-hydrogen CHP solutions. MWM have significant development experience in hydrogen-fuelled internal combustion engines for more than 20 years.

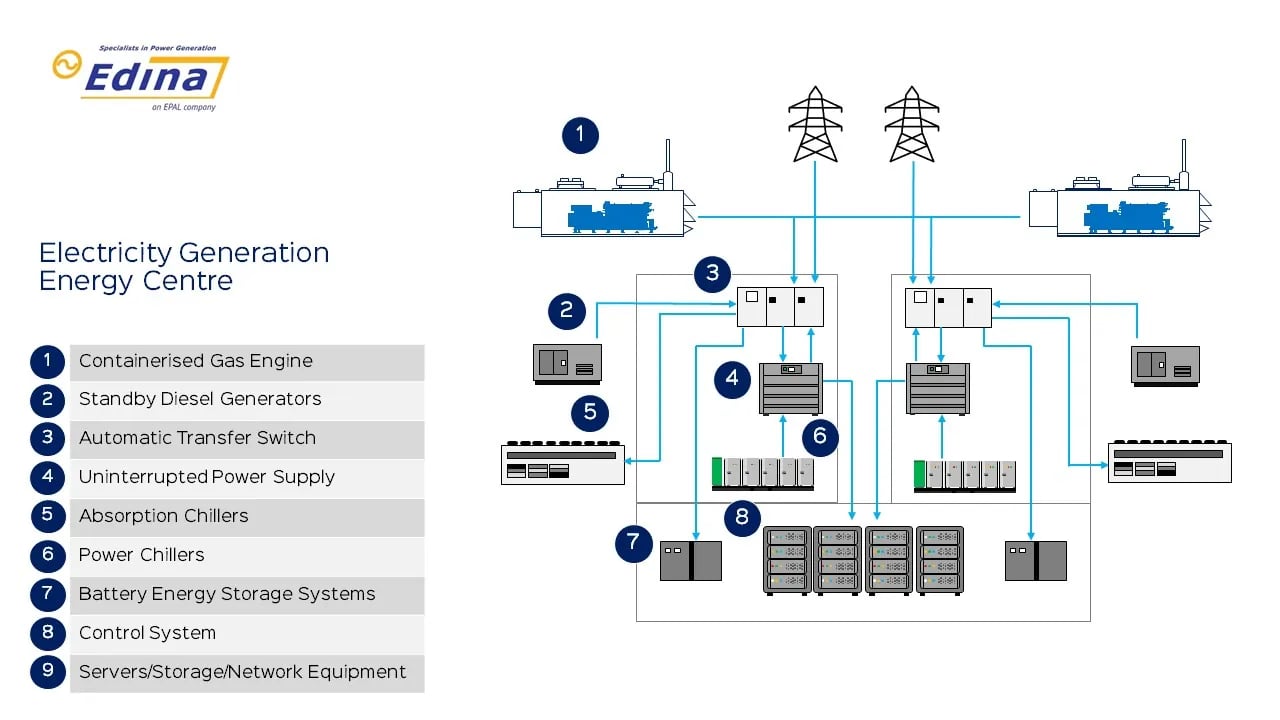

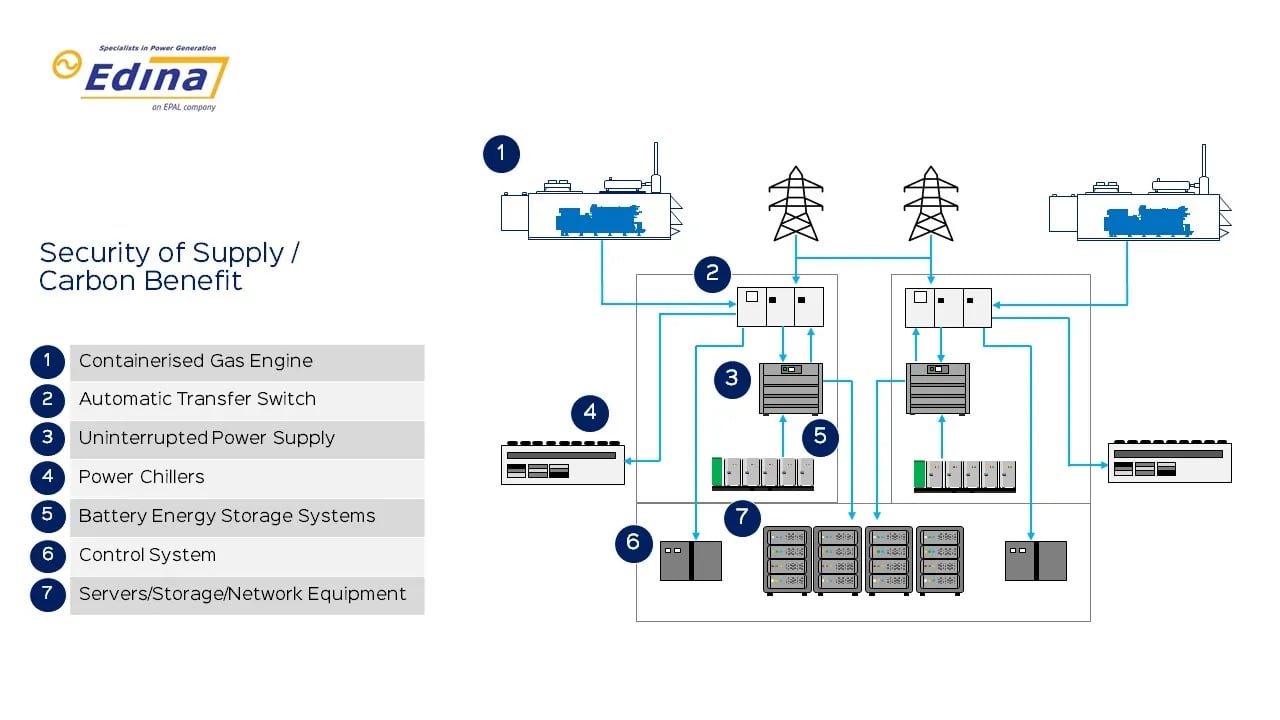

Data Centres have traditionally relied solely upon grid purchased power and the integration of emergency standby diesel generators and other power equipment to provide redundancy and resilience. The increase in data centre energy consumption, associated grid costs, and the increasing sustainability requirements provides a strong business case to adopt a decentralised approach and produce power on-site, close to the point of use using lean burn gas engines.

The data centres primary power is grid-supplied, and the provision of on-site gas engines add additional site resilience and capacity where networks are constrained. In this scenario, gas engines operate similarly to flexible generation plants and can produce electricity during high electricity price periods to manage the site operational costs.

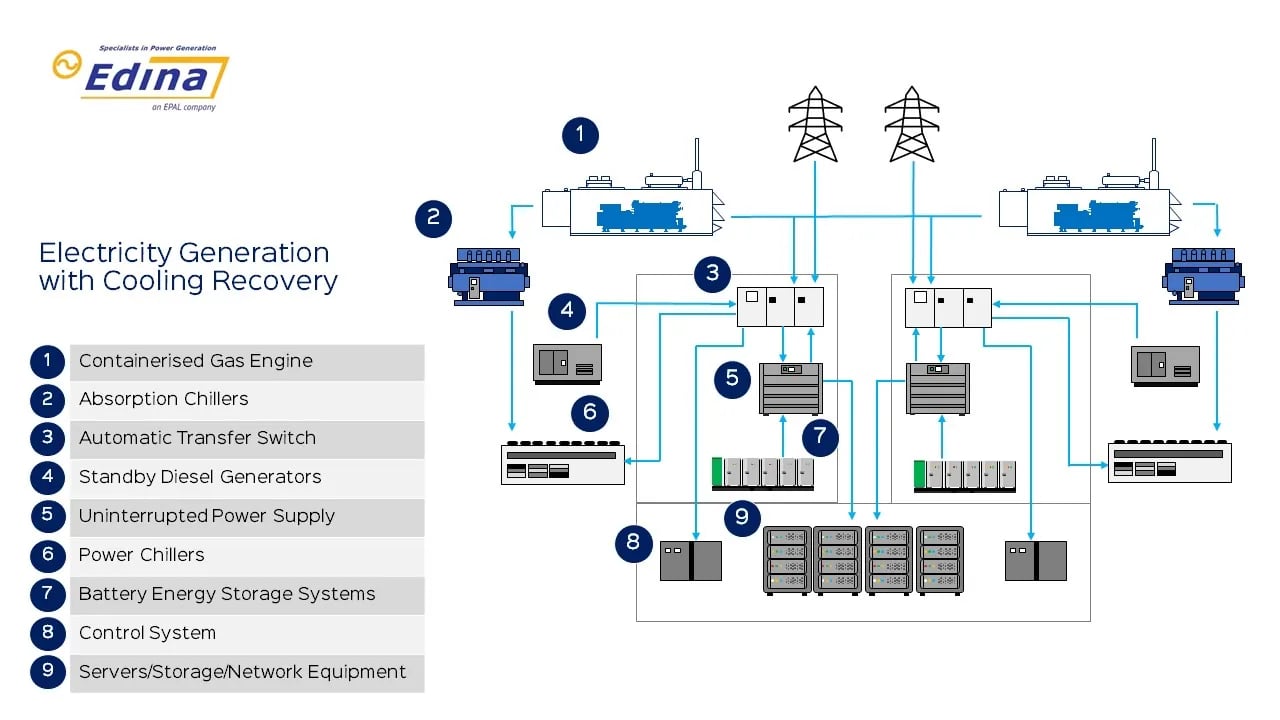

The data centres primary power is grid-supplied, and the provision of on-site gas engines add additional site resilience and standby power. Should there be a requirement for cooling, the data centre can introduce absorption chilling which can operate at temperatures as low as minus 5 degrees Celsius and support existing cooling infrastructure.

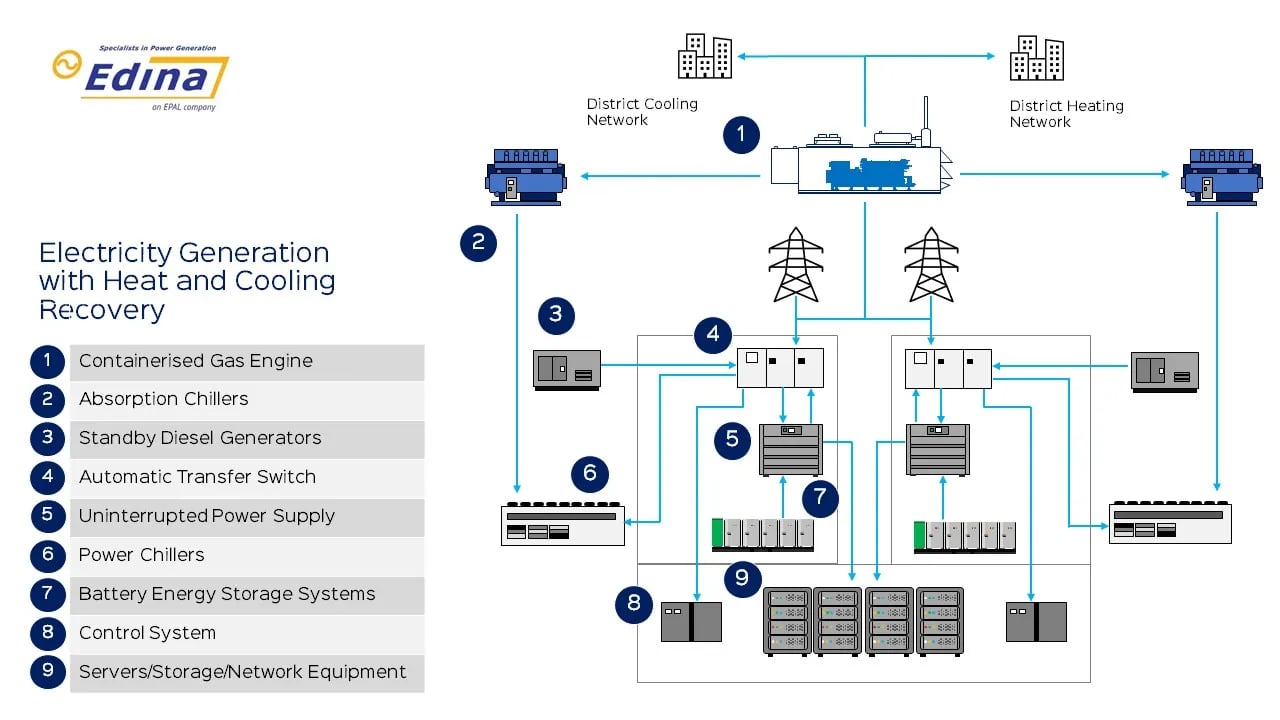

Primary power is supplied by the grid and gas engine assets provide secondary backup power adding additional site power resilience. Heat and cooling recovered from the engine can be used to power locally connected district energy networks ensuring optimised use of fuel source and engine asset.

In this scenario, gas engines displace diesel generation to provide secondary low carbon reserve power, thus reducing on-site carbon emissions. Further efficiencies can be realised once the gas network accepts blended hydrogen mixes.

In this scenario, gas engines displace diesel generation to provide secondary low carbon reserve power, thus reducing on-site carbon emissions. Further efficiencies can be realised once the gas network accepts blended hydrogen mixes.

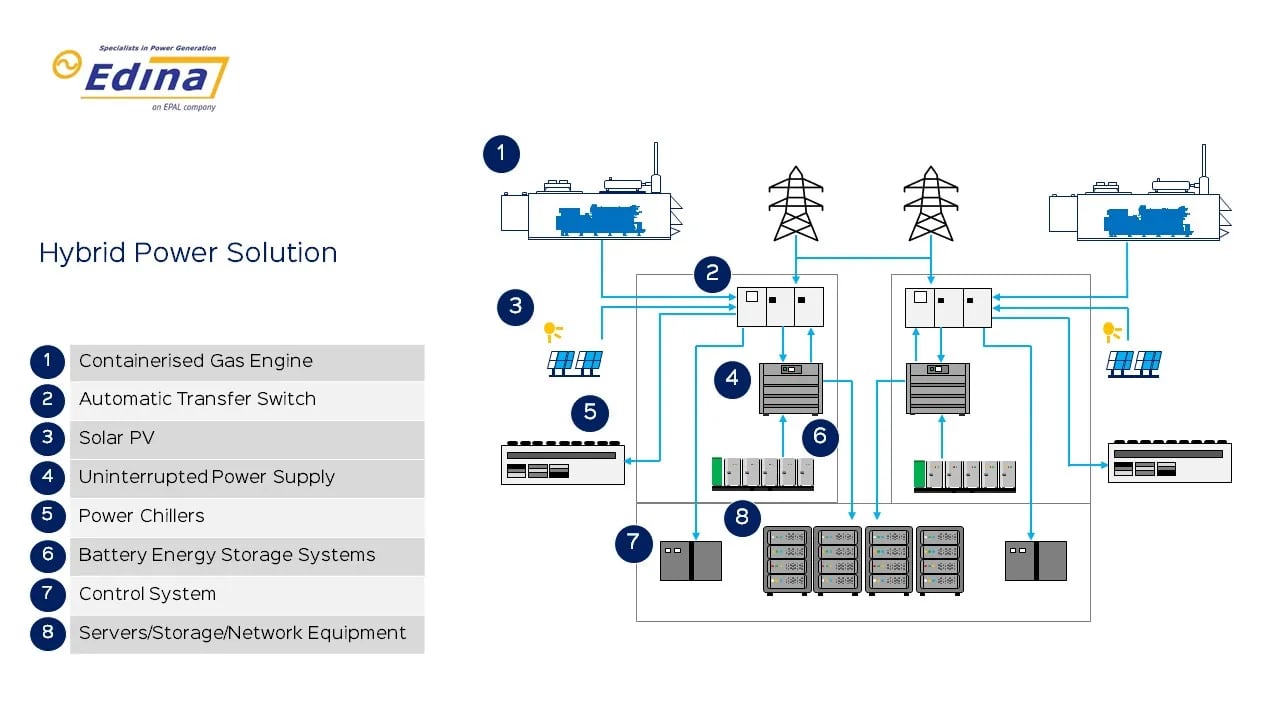

Gas engines can be integrated alongside a Battery Energy Storage System (BESS), wind, and solar photovoltaic technologies as part of a sustainable data centre power solution. Gas engines operating on low emission natural gas, renewable biogas, or hydrogen, provide reserve backup power and compliment renewable energy integration.

Battery storage can capture excess solar PV generation and store it for later use offsetting high time-of-day grid import charges or participate in demand side response services, offering asset flexibility and access to additional revenue streams.

Combined gas engines with BESS can also increase potential revenue streams from capacity grid services such as Fast Frequency Response (FFR), Primary Operating Reserve (POR) and Secondary Operating Reserve (SOR).

Under EirGrid’s Delivering a Secure, Sustainable Electricity System (DS3) programme, sites operating on renewable technologies could benefit from financial incentives for energy efficient plant performance.

Copyright © Edina. All Rights Reserved.