Search

The latest UK government statistics show that low fuel costs and a high spark spread are contributing to growth in Combined Heat and Power (CHP) generation.

Combined Heat and Power (CHP), also known as cogeneration, creates electricity and useful heat together in a single process, allowing organisations to reduce energy costs, while also supporting energy resilience and sustainability.

For the right sites, high efficiency CHP provides typical energy cost savings of 30-40% compared to grid supplied power and heat from boilers. This can often deliver a return on investment within 2 to 3 years.

Cogeneration provides sustainability benefitsand can also boost energy resilience by providing an off-grid power supply. This guards against the growing risk of electricity supply disruption.

The Digest of UK Energy Statistics (DUKES) provides a comprehensive picture of energy production, with specific chapters addressing an element of the contribution to the UK’s energy requirement. The statistics used in this article are all drawn from the CHP chapter of DUKES 2020.

Key findings:

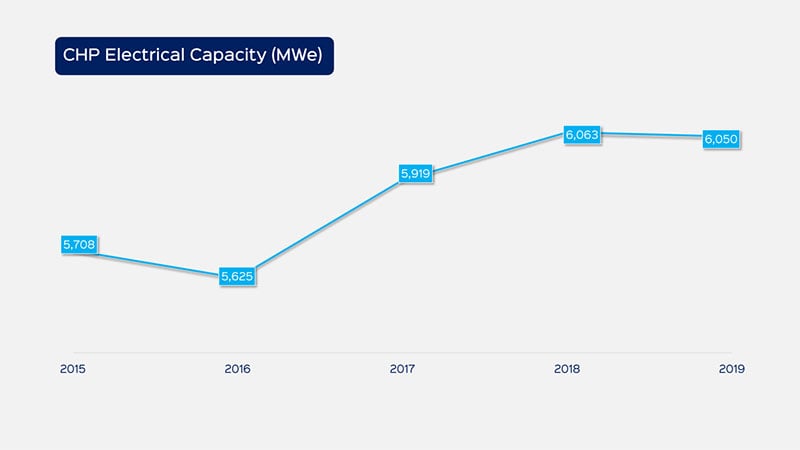

The figures show that the number of CHP schemes in the UK increased by 50 to 2,547 between 2018 and 2019 as more industrial sites, businesses, public sector organisations, district heating schemes and others invested in cogeneration.

The amount of ‘good quality’ electricity generated by CHP also increased by 2.2% to 23,461 GWh. Despite the increase in schemes and electricity produced, however, UK CHP capacity dropped by 13MWe to 6,050MWe.

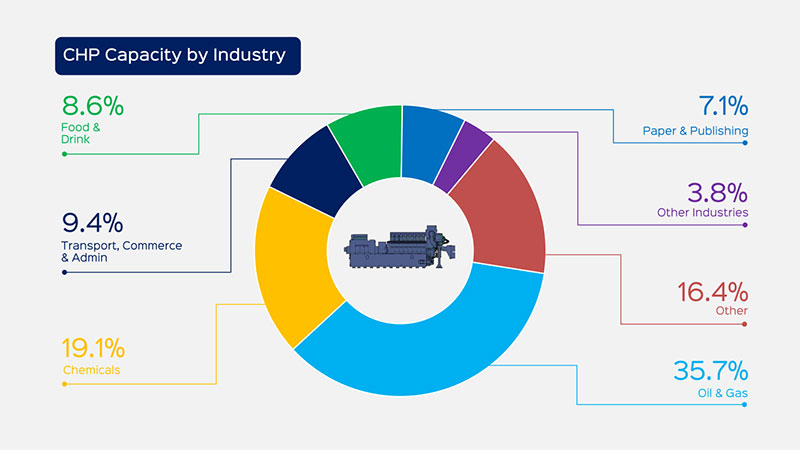

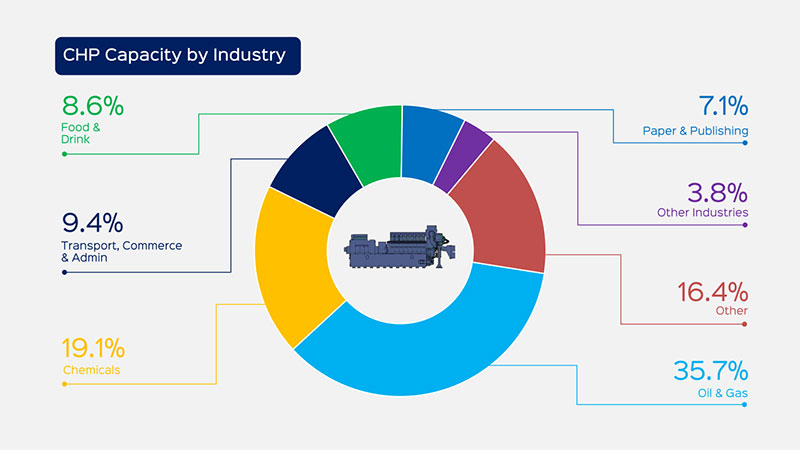

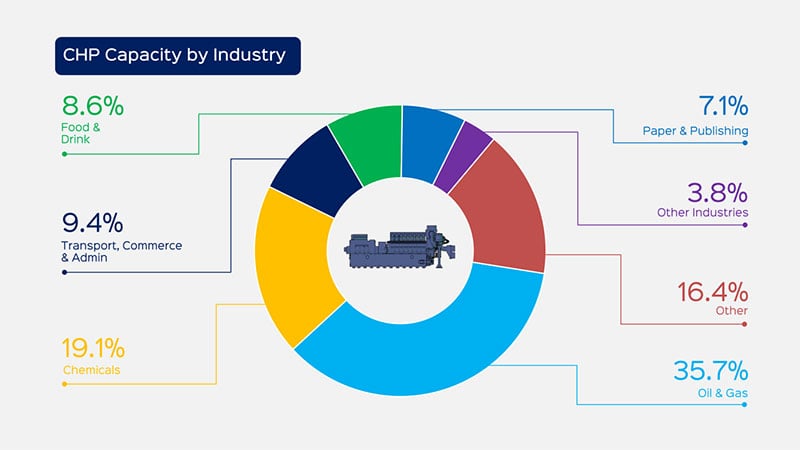

CHP remains a popular cost and carbon saving technology for heavy-industrial energy users. The oil and gas terminals sector were the largest CHP contributor by capacity in 2019, accounting for 35.7% of total CHP electricity capacity in the UK. The chemicals, food and drink, and transport, commerce and administration sectors also accounted for significant amounts of CHP capacity.

16.4% of UK CHP capacity is accounted for by ‘other’ sectors, including agriculture, community heating, leisure, landfill and incineration.

CHP is ideally suited to the industrial sector where energy intensive operations are run consistently. The ‘other industry branches’ sector, which includes textiles, sewage treatment, metal machinery, iron and other non-ferrous metals extraction accounted for 3.8% of the UK’s total CHP capacity.

Cost saving is the fundamental driver of CHP uptake, with businesses of all types and sizes investing in cogeneration to reduce heat and electricity bills.

Edina’s MWM CHP engines achieve extremely high efficiencies of 85% – 90%, almost twice as efficient as taking electrical energy from the grid and thermal energy from on-site boilers. This results in substantial savings on utilities costs.

The economic success of CHP is also determined by the positive ‘spark spread’. This is a simple calculation that compares the price of energy with the cost of fuel used to generate that energy.

Given that most CHP units are fuelled by natural gas, which over recent years has been significantly cheaper than grid electricity, there is a spark spread price advantage, which is illustrated by the latest UK energy statistics.

At the start of 2013, the spark spread started to increase and did so each quarter until the middle of 2016 when it peaked at 5.2. The spark spread began to fluctuate up and down between 2016 and 2018 but remained positive. Since 2018, however, the spark gap has increased consistently. In Q4 2019 it reached a peak of 5.6, the highest level since 2003.

For organisations investing in CHP, this healthy spark spread leads to energy cost savings and rapid financial returns. In many cases, CHP generators have provided payback times as quickly as two or three years, which can prove to be a smart investment when you consider that a typical CHP system has a lifespan of 10 to 15 years.

The cost returns of CHP are further enhanced by a range of government initiatives and policies designed to incentivise the uptake of Good Quality CHP in the UK.

These include:

Increasing demand for CHP is also being driven by the critical need for increased energy resilience. CHP can be configured to operate off-grid in ‘island mode’ to provide power security in the event of grid disruption. In August, a major power outage that affected businesses across England and Wales heightened concerns about the security of supply in the UK.

Power reliability is particularly important for manufacturers, who face heavy production losses, and data centres that can lose critical infrastructure in the event of a power cut. For these businesses and many others, energy resilience underpins the business case for CHP and onsite generation.

Read: How Queen Elizabeth University Hospital achieved security of power with CHP.

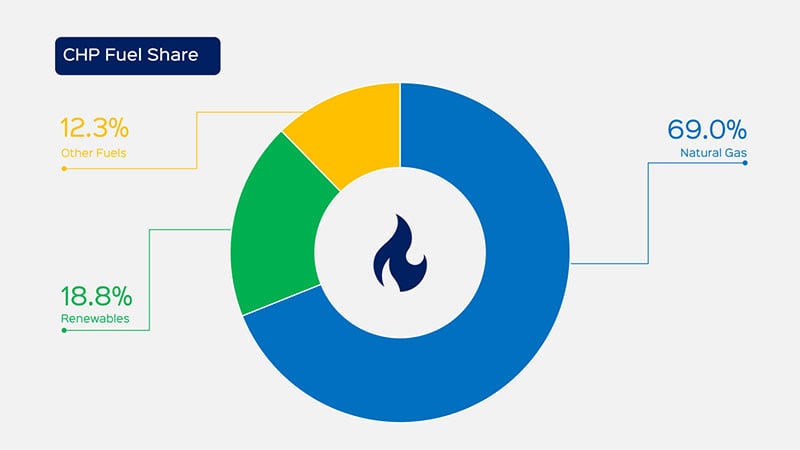

Natural gas remains the fuel of choice for most CHP generators. In 2019, 69% of the total fuel use was natural gas – the same as in 2018. CHP plants accounted for 7.9% of the UK’s total gas demand in 2019, up slightly from 7.3% in 2018. The proportion of electricity and heat generated through CHP using renewable fuels increased slightly from 17.4% in 2018 to 18.8% in 2019.

Solid biomass fuels accounted for the biggest share of renewable fuels, accounting for 58%, followed by gaseous renewable fuels (41%) and liquid renewable fuels (1.7%). Waste fuels accounted for 29% of the total fuel used in CHP in 2019, this is 0.4% higher than in 2018.

Calculating carbon emissions savings from CHP is complicated, because CHP plants can displace a wide variety of generators using different fuels and technologies, but the economics of the wholesale power market means that CHP is far more likely to displace higher carbon centralised gas or coal power plants, compared to energy generated by lower cost renewable sources.

Cogeneration provides a more efficient and cleaner solution to unabated gas power stations, which continue to make an important contribution to the UK power mix. ‘Good quality’ CHP schemes make at least a 10% primary energy saving compared to the separate production of heat and electricity. By generating heat and power onsite, organisations prevent the substantial transmission losses that occur from transporting electricity from remote power stations.

Government figures on the absolute carbon savings of installed CHP relative to fossil-fuel power stations in the UK show that there was a slight increase in the carbon savings, from 10.42 million tonnes of carbon dioxide (MtCO2) in 2018 to 10.47 MtCO2 in 2019.

Read: How Arla Foods is using CHP to achieve its zero carbon vision of the future.

Edina is market-leader in the provision of CHP and is the exclusive UK and Ireland distributor for high efficiency MWM gas engines. From its sites across the UK and Ireland, Edina supplies full service and maintenance coverage supported by 24 hours a day, 7 days a week, 365 days a year field service engineering support and remote monitoring, control systems monitoring and remote support from our UK Head Office. This ensures exceptionally high levels of CHP efficiency and availability to promote operational resilience. Our full turnkey/EPC power solution is creating competitive advantage and sustainability savings for organisations across all sectors.

To discuss CHP feasibility for your organisation, speak to a member of the Edina team today and call: +44 (0)161 432 8833 or email us.

These Stories on Combined Heat and Power

If you are looking to take control of your energy needs and produce power close to the point of use, we would love to hear about your project requirements and help power your future. If you would like to discuss your project, please contact us.

Copyright © 2025 Edina. All Rights Reserved.