Search

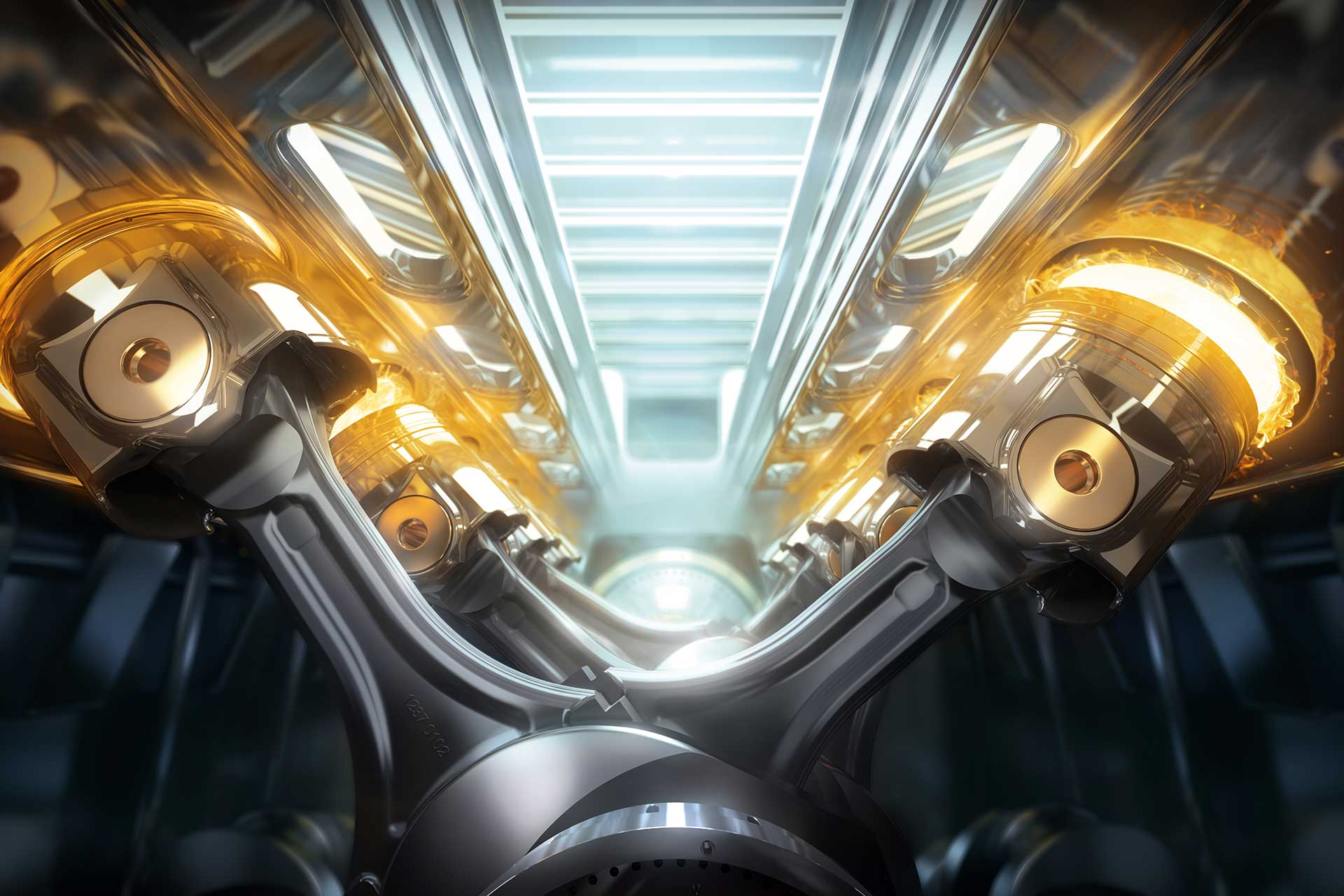

MWM gas engines are highly efficient at the conversion of gas into electrical power. Should there be a local requirement to recover the heat emitted from the electricity generation process, then Combined Heat and Power (CHP) application presents a greater return on investment.

MWM is a world innovator of gas engine technology. Founded in 1871 by visionary and automotive pioneer Carl Benz, MWM continue to develop cutting-edge technology and today remain one of the leading and world renowned in the field of gas engine technology.

Significant energy cost savings of up to 30% and payback of 2-5 years

Greater operational resilience and security of power supply

Improve business competitiveness and inroads into R&D

Operational cost savings can be reinvested in the deployment of renewable energy technologies to further enhance green credentials

Budgeting certainty and control over rising power costs

Reduced transmission and distribution losses as power is produced and consumed at the point of use

Advantageous spark-spread due to low gas prices relative to power costs

Fast project set up and installation

Flexible power opportunities

Finance options available

10-15 year asset lifespan

Low operating costs

When connected to an alternator to produce electricity, the MWM gas engine is typically known as a generator or a genset. The generator is then connected to a site’s electrical infrastructure via an electrical circuit breaker, which is used to synchronise electrical supply and to operate in parallel to the electricity grid.

Electricity generation using gas generators are mainly used for continuous base load generation, standby peaking plants to balance the electricity grid and demand side generation.

Where there is a stable source of fuel, such as natural gas, biogas, or coal gas to power the generators, base load power plants produce as much power as possible from the fuel available or the station capacity and export it to the electricity grid for income generation.

Alternatively, should the power plant be isolated from the electricity grid, the electricity produced can be used to power local off-grid infrastructure through Island Mode Operation.

Peaking Plants, or peak lopping plants, are gas fuelled power plants that are designed to generate power to support and balance the fluctuating power demand within the electricity grid. Unlike base load generation, peaking plants typically operate in standby mode when not in use and are called to operate by the electricity grid when there is a demand to supply electricity.

Due to their flexibility and rapid response to supply electricity, peaking plants are ideally placed to balance system stress within the electricity network and allow for the growth of renewable energy onto the electricity grid.

Demand side generation is used when the site consumes a significant amount of power from the electricity grid.

The generation of power is used to offset the cost of importing power, but not export to the electricity grid. This is used when the price of imported power is very high due to the Transmission Network Use of System (TNUoS) and Distribution Use of System (DUoS) charges, typically between 4pm and 7pm on weekdays.

However, due to the increasing additional charges on importing electricity, the economics of demand side generation is such that significant hours of operation are feasible, even to continuous operation.

Furthermore, if the heat is recovered from the generator, then this too offers a greater return on investment through the Combined Heat and Power (CHP) process.

Edina can provide flexible finance options to suit your requirements, including low cost power purchase contracts and energy service agreements. This could mean zero capital investment with instantaneous energy savings, thus freeing up CAPEX for alternative strategic investments.

We can either supply a single engine only or deliver the full EPC contract to include design, build, engineering, project management, integration of auxiliary equipment and balance of plant, engine commissioning and full 24 hours a day, 7 days a week, 365 days a year service and maintenance of the equipment over a 15-year life cycle.

Across our almost 40-year history we have the requisite knowledge across the design, engineering, project management and maintenance of gas-engine fuelled power plants and have a growing installed capacity of over 1,000MW electrical across the UK, Ireland, Australia and India.

Copyright © Edina. All Rights Reserved.