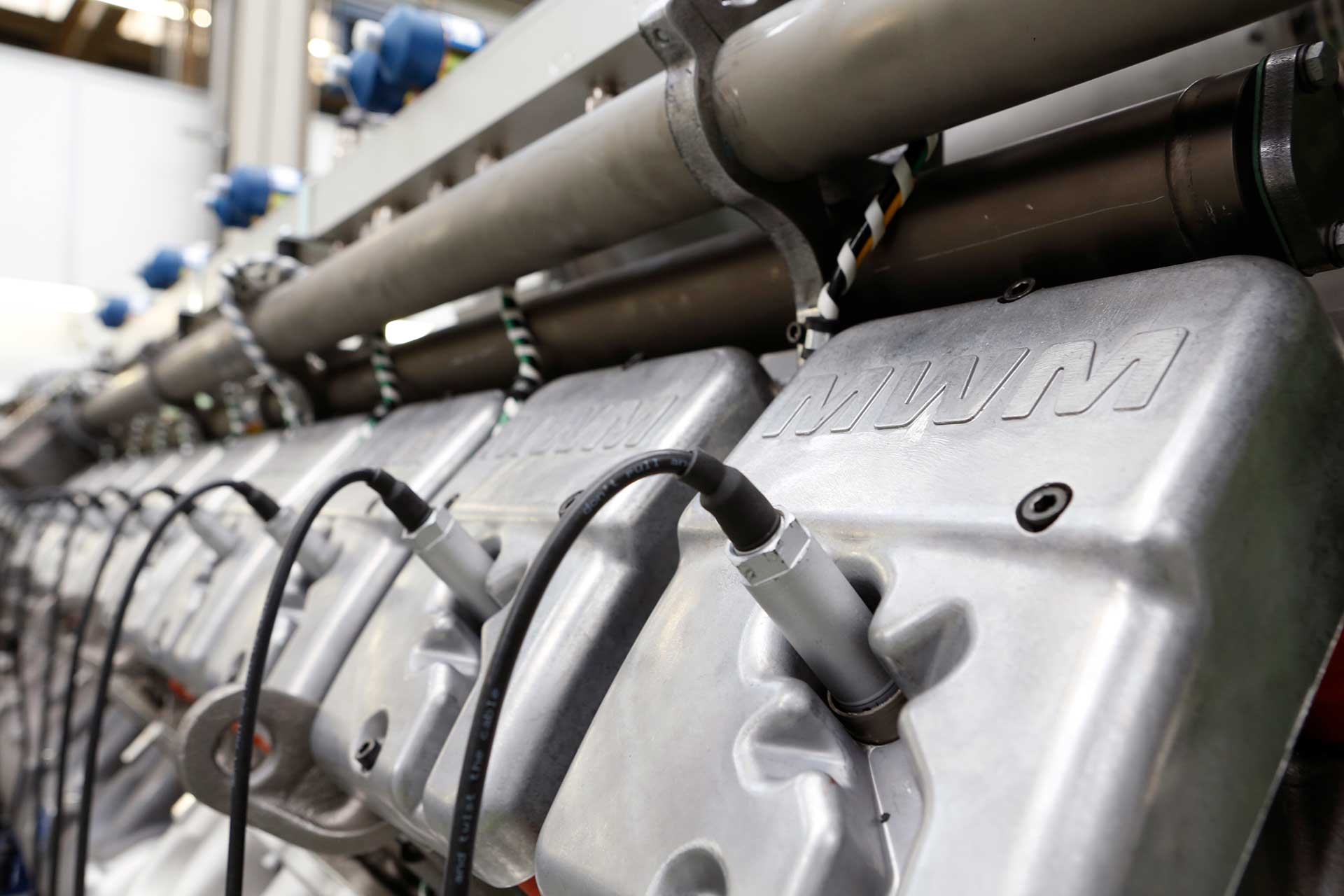

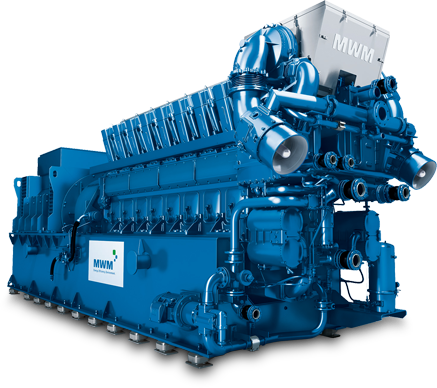

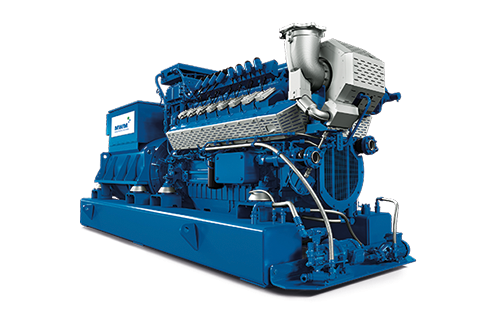

The MWM gas engines of the TCG 2032 series are perfectly geared to the challenges of a dynamic market environment. In the power range of 3,000kWe - 4,500kWe reliability, flexibility, efficiency and environmental compatibility are ensured along with low life-cycle costs. In this way, they meet the high requirements of a wide range of applications and are highly profitable.

Output ranges from 3,333 to 4,500kWe

Operates on all gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas, biogas

Mainly used in large IPP projects with up to 100,000kWe

The series features superb reliability and low operating and maintenance costs

High reliability

Low operating costs

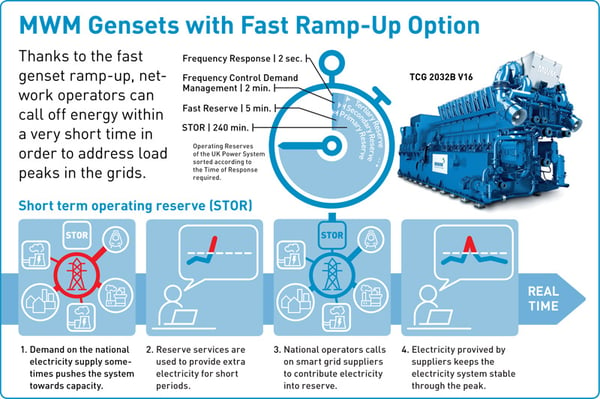

Also available with fast ramp-up option for the gas engine TCG 2032B V16

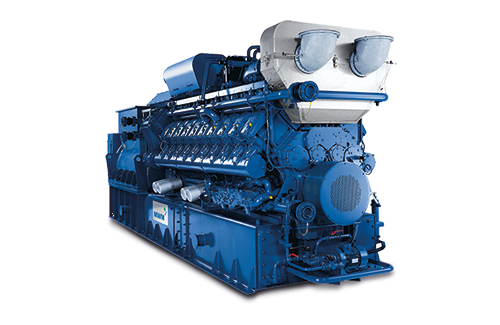

TCG 2032B V16 gas engine with fast ramp-up option - 4.5MWe gas engine for a quick start:

TCG 2032B V16 gas engine with fast ramp-up option - 4.5MWe gas engine for a quick start:

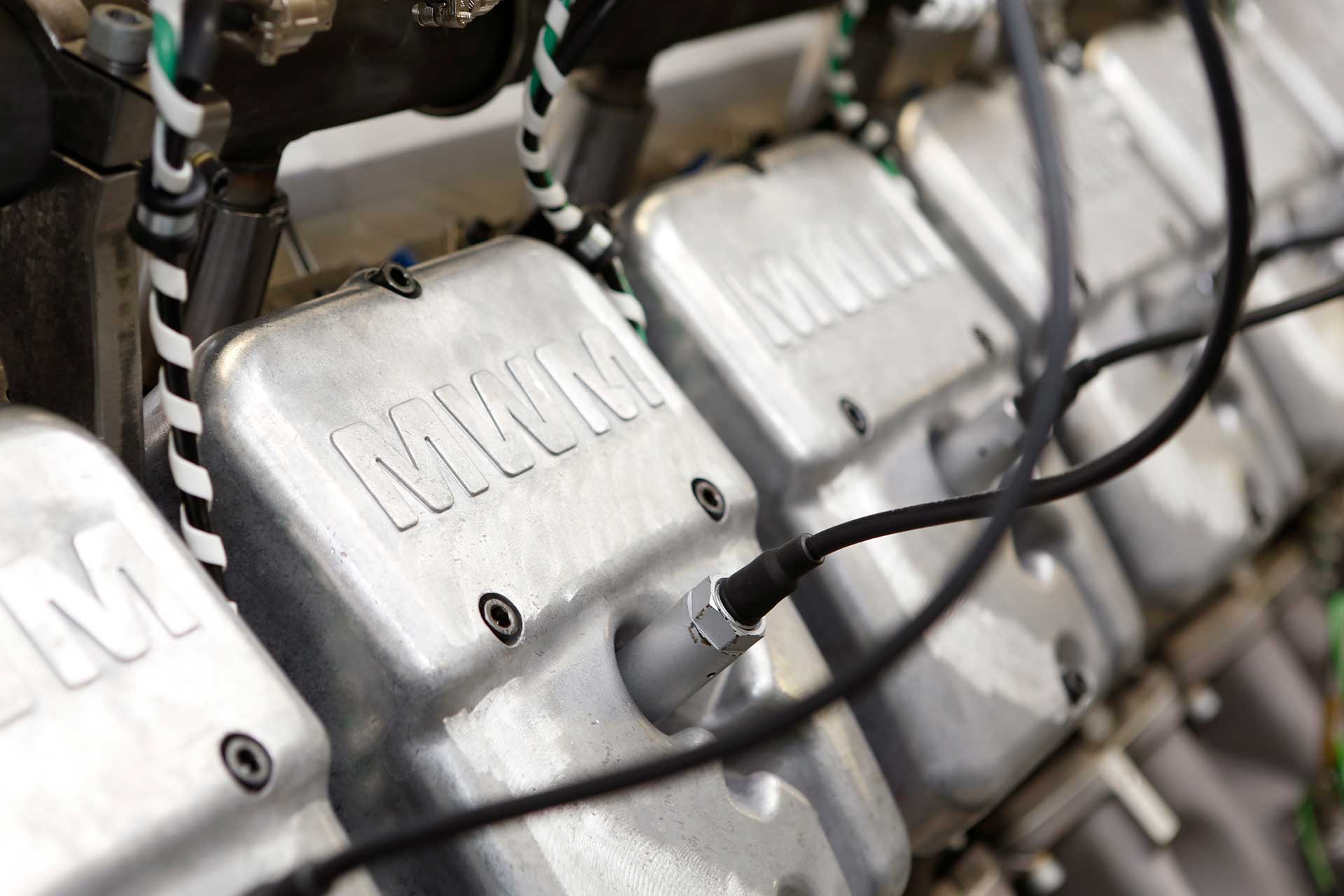

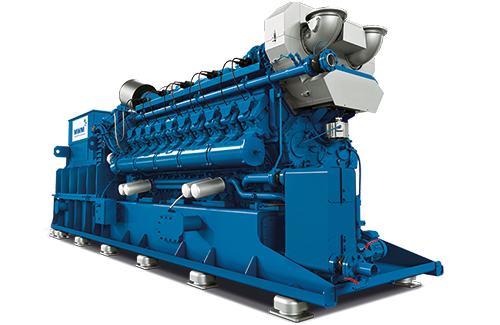

The optimised maintenance concept with cylinder units simplifies accessibility and, along with the reduction of the number of different parts, minimises the time required for maintenance.

This can save you up to 20 percent in service costs. At the same time, you profit from up to 30 percent less lubricating oil consumption compared to other engines.

Thanks to the extended service intervals, the TCG 2032 gas engine runs up to 200 hours longer per annum than comparable products.

The major overhaul is scheduled after 80,000 operating hours.

The particle-free combustion, with pre-chamber spark plugs, extends the service intervals for the exhaust gas heat exchanger and reduces service costs compared to other combustion methods.

Major components such as pistons, conrods, spark plugs and cylinder heads have been improved to withstand the greater power output and to deliver increased electrical efficiency.

The interaction of all components has been improved even further. All components relevant for efficiency and power output are monitored by the TEM (Total Electronic Management). The new, upgraded wastegate in particular ensures a more efficient operation with changing conditions.

This is also the case when the gas composition is fluctuating – thanks to fast response times due to the temperature monitoring for each cylinder. TEM not only controls the engine… but the entire system… including heat extraction.

The high-pressure turbocharger A140, with an improved wastegate, allows operation with a broader air intake temperature range and up to higher altitudes.

| TCG 2032 | V12 | V16 | V16 B |

| Engine type | 50 Hz | 50 Hz | 50 Hz |

| Electrical output | 3,333kW | 4,300kW | 4,500kW |

| Mean effective pressure | 20.0 bar | 19.4 bar | 20.3 bar |

| Thermal output ± 8% | 3,238kW | 4,164kW | 4,259kW |

| Electrical efficiency | 43.9% | 42.7% | 43.2% |

| Thermal efficiency | 42.6% | 42.7% | 43.2% |

| Total efficiency | 86.5% | 86.8% | 87.8% |

| Power to heat ratio ** | 1.03 | 1.03 | 1.03 |

| TCG 2032 | V16 |

| Engine type | 50 Hz |

| Electrical output | 3770kW |

| Mean effective pressure | 17.0 bar |

| Thermal output ± 8% | 3496kW |

| Electrical efficiency | 43.0% |

| Thermal efficiency | 39.8% |

| Overall efficiency | 82.8% |

| Power to heat ratio ** | 1.08 |

* With 5% O2 and dry exhaust gas

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

| TCG 2032 | V12 | V16 | V16 B |

| Engine type | 50 Hz | 50 Hz | 50 Hz |

| Bore / stroke | 260/320mm | 260/320mm | 260/320mm |

| Displacement | 203.9dm3 | 271.8dm3 | 271.8dm3 |

| Speed | 1000min-1 | 1000min-1 | 1000min-1 |

| Mean piston speed | 10.7m/s | 10.7m/s | 10.7m/s |

| Length | 7860mm | 9271mm | 9272mm |

| Width | 2660mm | 2790mm | 2790mm |

| Height | 3390mm | 3390mm | 3390mm |

| Dry weight genset | 43100kg | 51400kg | 51400kg |

| TCG 2032 | First service (check valve clearance) * | Spark plug change | Cylinder head inspection | General overhaul |

| Natural gas | 4000 Oh | 20000 Oh | 40000 Oh | 80000 Oh |

Oh – Operational Hours

We have supported clients across a wide range of industry sectors to achieve energy efficiency, reduce emissions and operational costs, maintain power resilience, and improved business competitiveness.

CHP reduces annual operational costs by €1million for global eye health company.

Copyright © Edina. All Rights Reserved.