Search

Associated Petroleum Gas (APG), also known as Flare Gas, or Associated Gas can be utilised within a high-efficiency gas engine to produce electricity and heat via Combined Heat and Power (CHP).

APG is a form of natural gas, which accrues at the extraction of crude oil and its conversion to usable products.

Historically, the gas was burnt off in gas flares and was classed as a waste product. However, the negative environmental impact in doing so, coupled with an increase in energy demand, has seen its utilisation risen in power generation application.

Using a gas engine, flare gas can be converted into electricity and heating to be used on-site, without the need for additional remote diesel generation. This helps reduce carbon emissions from diesel fuel consumption and operational costs.

Flare gas, when used in gas engines, includes many benefits:

Reduces operational costs associated with diesel generators

Waste product is used to power on-site infrastructure

Reduces carbon emissions

A local fuel supply that produces stable electrical and thermal power

|

Compound

|

Formula

|

%

|

|

Methane

|

CH4

|

75-85

|

|

Ethane

|

C2H6

|

3-8

|

|

Propane

|

C3H8

|

3-8

|

|

Butane

|

C4H10

|

2-6

|

|

Nitrogen

|

N2

|

1

|

|

Carbon Dioxide

|

CO2

|

>0.15

|

Other impurities may be Hydrogen Sulphide (H2S. The higher number carbon molecules will reduce the methane number of the gas which can cause “knocking” in the engine, which may have to be de-rated.

Other forms of Associated Gas are Coal Bed Methane where natural gas is extracted directly from an underground coal seam and shale gas, which is very topical due to its extraction by ‘Fracking’.

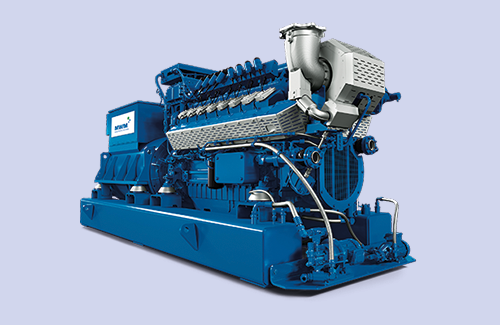

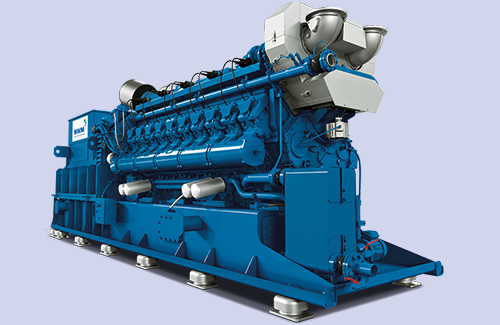

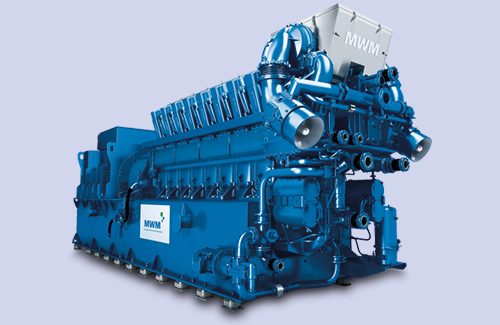

APG is another gas type that can be used with MWM generation sets and we provide solutions for the optimum processing and safe use of this gas, which would otherwise be flared unused.

Depending on its source, APG may have a high content of liquid hydrocarbons which will need to be separated before use or transportation.

The MWM range of gas engines are perfectly capable in operating on Associated Petroleum Gas and our containerised solution is especially tuned for this application.

Copyright © Edina. All Rights Reserved.