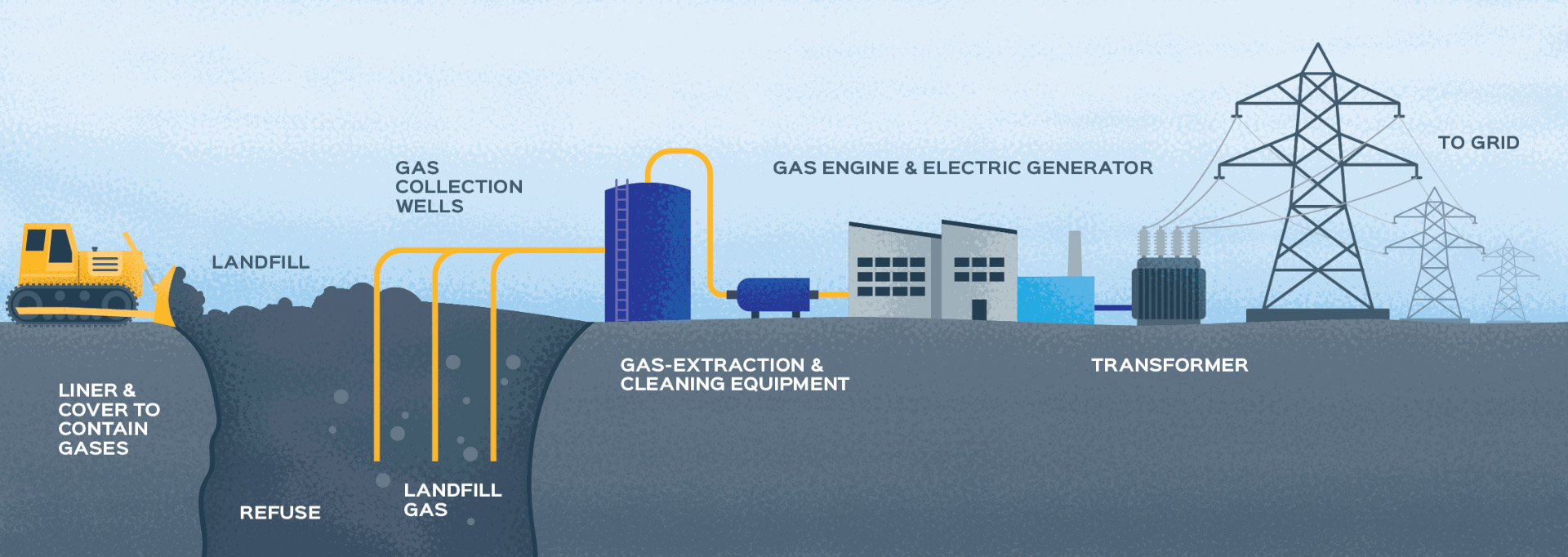

Landfill gas is produced by the uncontrolled anaerobic decomposition of organic waste in the landfill.

The methane emitted from landfills has an up to 25 times higher global warming potential than carbon dioxide. By collecting and using this gas within a gas engine, the environment is protected on a high level.

All current and recently closed UK landfill sites have gas collection systems to flare the gas or have adopted Combined Heat and Power (CHP) application to collect, process and treat the available landfill gas to generate electricity.

Although the UK Renewable Obligation support for new and additional landfill gas schemes has been reduced, the rising energy costs and power prices make CHP application attractive for landfill sites.

Reduce the environmental impact

Produce electricity, reducing energy costs

Provide site security of power

Exported energy used as income generation

Landfill gas composition primarily consists of methane (45-65%), carbon dioxide (15-45%) and nitrogen (10-35%).

| Compound | Formula | % |

| Methane | CH4 | 45-65 |

| Carbon Dioxide | CO2 | 20-45 |

| Nitrogen | N2 | 10-35 |

| Oxygen |

O2 |

0-10 |

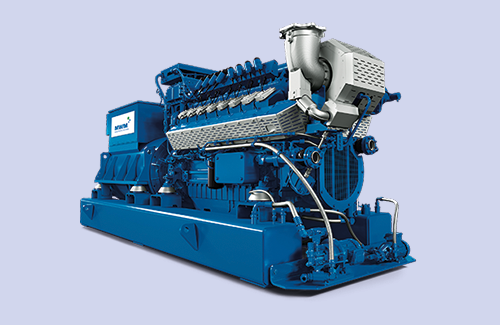

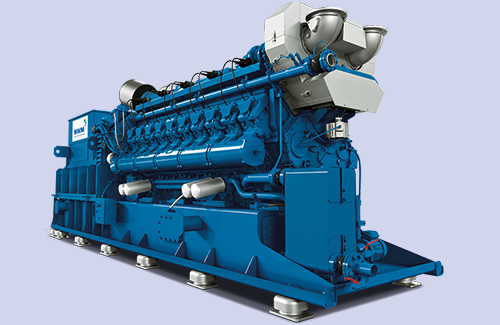

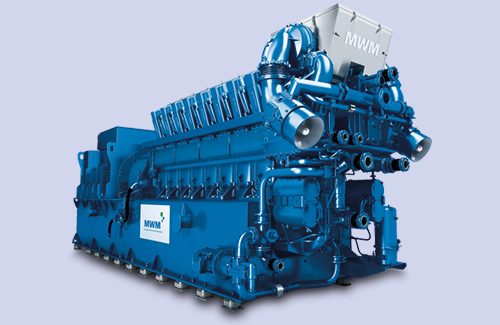

To maximise the site potential return on investment, MWM reciprocating gas engines deliver market-leading electrical and thermal efficiency, low operating and servicing costs and high reliability and availability.

MWM have longtime experience with landfill gas applications with over 700 gensets operating in 400 landfills producing over 600MWe installed power worldwide.

The MWM range of gas engines are perfectly capable in operating on landfill gas and our containerised solution is especially tuned for this application.

Copyright © Edina. All Rights Reserved.