Search

Biogas is the product of the anaerobic fermentation of organic material in a digester. As a renewable fuel source, Biogas can be utilised within gas engines to produce electricity and heat through Combined Heat and Power (CHP) provision.

Alternatively, biogas can be cleaned via biogas upgrading techniques (typically by water scrubbing and membrane separation) which removes any CO2 and other contaminants present in the biogas to produce pure biomethane (also known as Renewable Natural Gas) which can be injected into the gas distribution network or used as a renewable fuel within gas engines.

Edina is the official UK and Ireland distributor for MWM gas engines which are capable of utilising difficult fuel gases such as biogas, landfill gas and sewage gas to produce electricity.

Reduced energy bills – typically saving a minimum of 10% on previous energy expenditure

Typical return on your investment payback in 3-4 years

Significant reductions in carbon emissions

Maintain security of power supply

Improve financial forecasting (energy spend) and business competitiveness

Improve corporate ethics

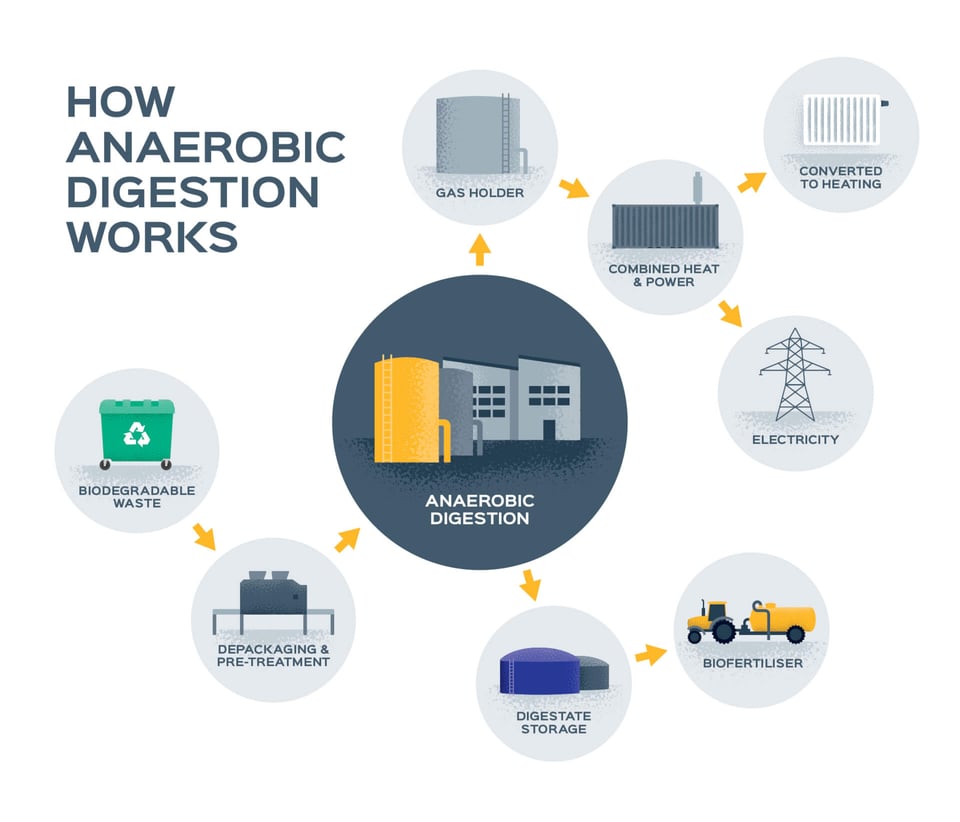

Biogas originates from the anaerobic digestion (AD) of organic matter within a digester. At anaerobic digestion, the substrate is fermented under the exclusion of oxygen and with the help of microorganisms.

The following are suitable as initial materials for the technical production of biogas:

Biogas composition primarily consists of methane (50-75%) and carbon dioxide (25-50%) and may contain small amounts of nitrogen or hydrogen. Contaminants in the biogas can include sulphur or siloxanes, but this will depend upon the digester feedstock.

| Compound | Formula | % |

| Methane | CH4 | 50-75 |

| Carbon Dioxide | CO2 | 25-50 |

| Nitrogen | N2 | 0-10 |

| Hydrogen | H2 | 0-1 |

| Hydrogen Sulphate | H2S | 0-3 |

| Oxygen | O2 | 0-0 |

Anaerobic Digestion to produce biogas (essentially a mixture of Methane and Carbon Dioxide) has been an established process in the sewage industry for nearly 100 years. From development in the sewage industry, it has been used for solid and liquid waste treatment in industrial and municipal applications and more recently for purpose grown agricultural crops.

The overreaching advantage of Anaerobic Digestion over alternate process technologies, is that it is energy producing. The feedstocks are all organic in nature and hence the energy produced is classed as Renewable Energy.

The biogas produced can be burnt in a boiler to produce heat but nowadays the most efficient use of biogas is to utilise a gas engine to produce CHP. Electricity and heat generation from biogas plants is now an important contribution towards greater use of renewable sources and part of the Government response to combat climate change.

Production of renewable power through Combined Heat and Power provision

Disposal of problematic wastes

Diversion of waste from landfill

Production of a low-carbon fertiliser

Avoidance of landfill gas escape and reduction in carbon emissions

The scope of supply of a biogas CHP installation could start at the biogas pipe work at the digester. It may contain several discrete process elements all of which may or may not be required. These are usually:

All the above would need to be monitored and controlled with data fed back to a central control system. The degree of sophistication of an installation is usually linked with the overall size of the project. Larger size plant with significant electrical generation/biogas production will have a greater capital expenditure scope and would install more of the above elements. This would give greater gas conditioning and better process reliability.

The MWM range of gas engines are perfectly capable in operating on biogas and our containerised solution is especially tuned for this application.

We have supported clients across a wide range of industry sectors to achieve energy efficiency, reduce emissions and operational costs, maintain power resilience, and improved business competitiveness.

Copyright © Edina. All Rights Reserved.