Search

Managing energy costs and the requirement to improve sustainability measures within local authorities and municipalities can be realised through Combined Heat and Power (CHP) application.

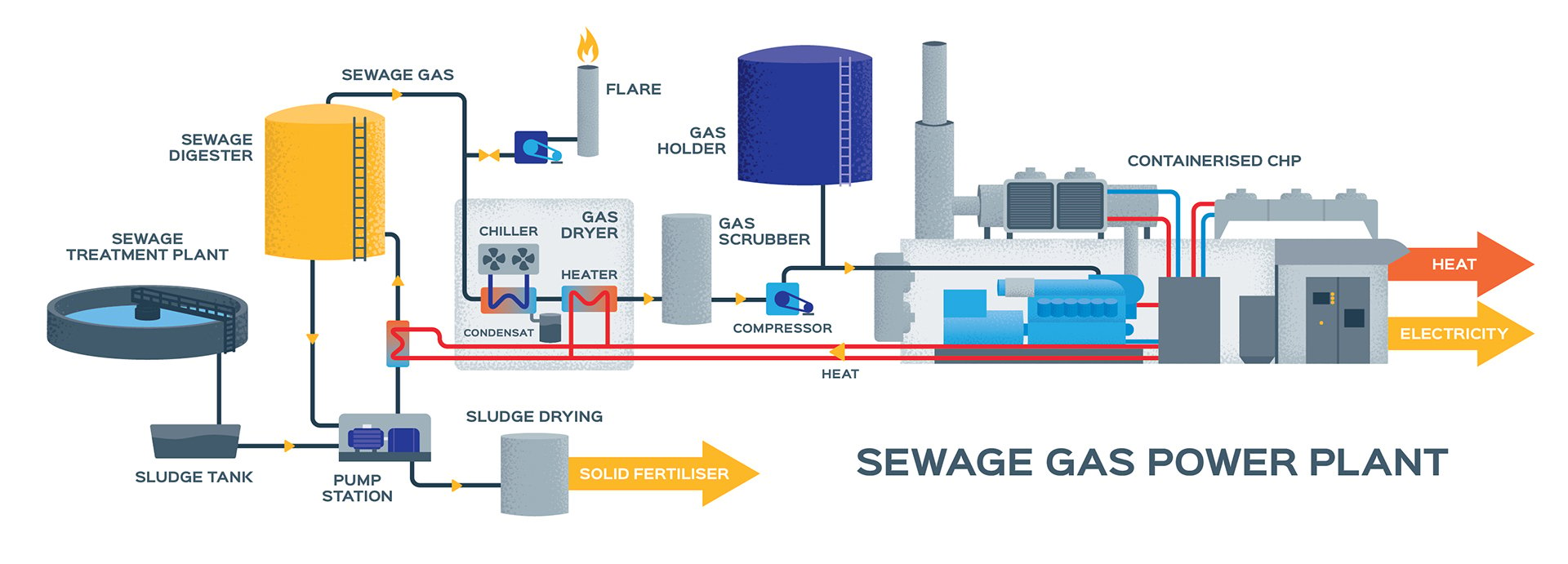

Through the process of anaerobic digestion, the biogas produced by the wastewater digesters used in the water treatment process is captured and used within MWM gas engines to power the waste treatment plant. The electricity produced can either be used on-site to reduce grid imported electricity costs or exported to the electricity grid for income generation.

Recent environmental requirements and process innovations have led to advanced anaerobic digestion where the sewage sludge is pre-treated thermally and/or enzymically before the digestion process. This pasteurises the sludge and increases conversion to biogas. Often the process requires steam for heating and this is produced from the exhaust heat of the Combined Heat and Power (CHP) plant.

Using sewage gas for electricity generation can provide many benefits, including:

Renewable energy generated from a waste material through Combined Heat and Power (CHP)

Reduces operational costs

Export power used as an income generation tool

Reduces CO2 emissions

Cost-effective and proven technology

Mogden Sewage Treatment Works utilises a 6MWe Combined Heat and Power (CHP) plant which replaced the sites existing dual fuel system. The CHP installation significantly improves serviceability, availability, power generation and reduces carbon emissions.

Elsewhere, the facility is capable of treating 50 percent more sewage waste to cater for London’s growing population and meets the tighter effluent quality standards set by the Environmental Agency.

Edina remains the preferred biogas CHP supplier, installer and maintenance provider on most advanced digestion and anaerobic digestion projects commissioned in the UK, with over 80MWe installed across the sewage and wastewater treatment sectors.

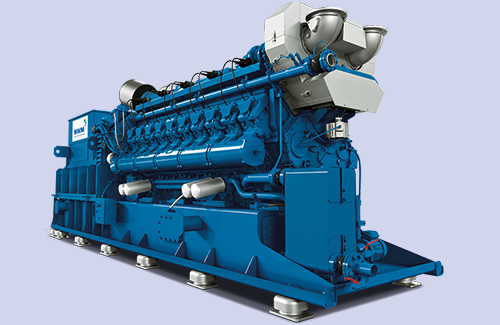

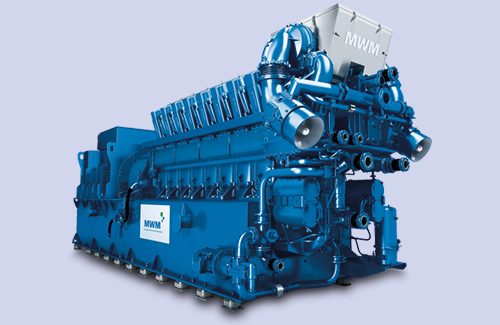

Globally, MWM has a wealth of longtime experience with sewage gas applications and over 300 gensets operating with more than 400MWe installed power worldwide.

Sewage gas composition primarily consists of methane (50-75%) and carbon dioxide (15-45%) and may contain small amounts of nitrogen. Contaminants in the sewage gas can include hydrogen sulfide and siloxanes.

| Compound | Formula | % |

| Methane | CH4 | 50-75 |

| Carbon Dioxide | CO2 | 15-45 |

| Nitrogen | N2 | <1 |

- Heating value between 6 – 6,4 kWh/m³

- Variable methane contents due to organic feed materials

- Under thermal influence siloxanes turns into sand

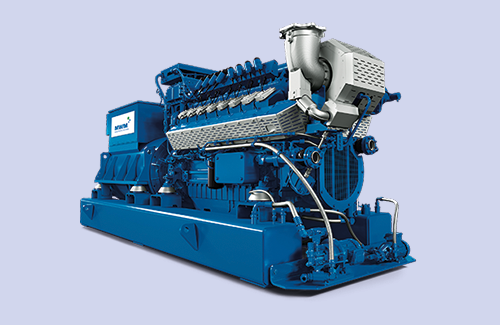

The MWM range of gas engines are perfectly capable in operating on sewage gas and our containerised solution is especially tuned for this application.

We have supported clients across the sewage treatment and waste water treatment sector to achieve energy efficiency, reduce emissions and operational costs, maintain power resilience, and improved business competitiveness.

Edina CHP reduces operational costs by £100k per week at second largest sewage treatment works in the UK.

Edina 3.2MWe CHP powers Yorkshire Water’s Esholt Sewage facility saving £1.3million in energy costs.

Edina 6MWe CHP powers one of Europe’s largest Sewage Treatment Works at Beckton.

Copyright © Edina. All Rights Reserved.